The thoroughbred blue water cruiser emerges

The deck section is traditionally constructed separately to the hull. This is because of the laminating required to build the longitudinal and traverse stiffeners, bulkheads, and flooring. Also the installation of the engine, generators and tankage must be carried out before the deck is bonded to the hull. However Kraken Yachts are designed to allow boat owners to remove the engine and generator later if required.

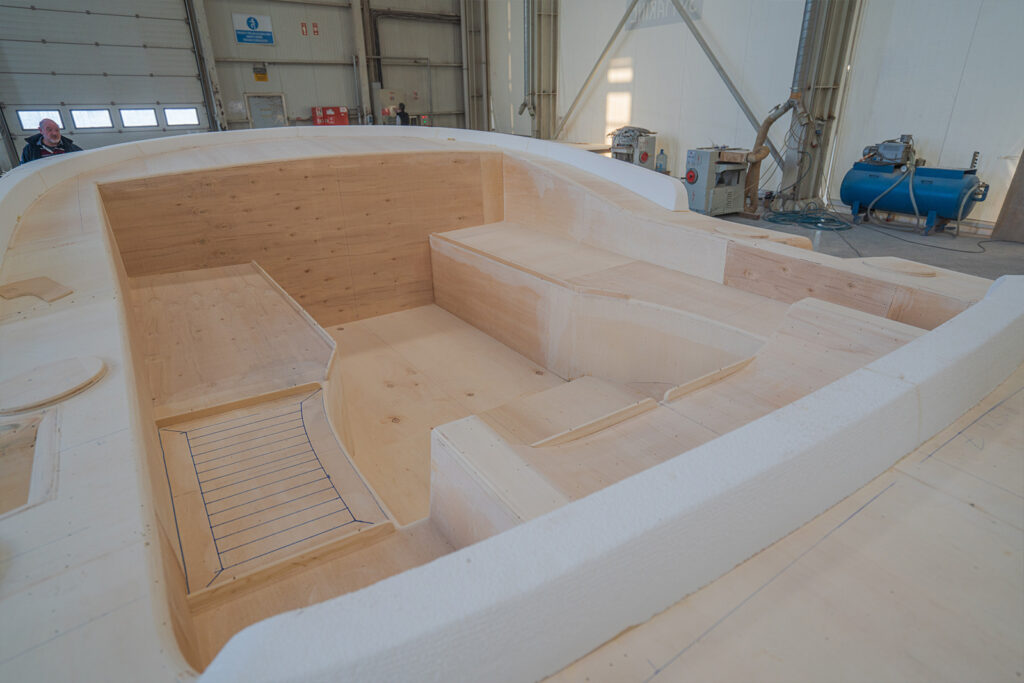

The carpentry team use wooden planking to sculpt the shape of the deck and cockpit for the plug while the hull undergoes lamination with a layer of bi-axial fibreglass cloth. Once dry, the hull is then covered with filler and faired. The sanding process is the most time consuming part but a perfectly smooth finish is required before painting. Once complete, the hull is painted, varnished and made ready to form the female hull mould.

Then the team move back to the deck: once the basic shape is constructed, work begins on the fine detail. Features such as the Kraken moulded bulwark and deck gear plinths need to be sized and made from wood before the plug is ready for lamination. It is our firm belief that the crew should not have to leave the safety of the cockpit when needing to furl, reef or trim the sails. Careful consideration is therefore made with each Kraken yacht on where deck gear is placed so each winch, organiser or clutch is easily reached by a short-handed crew. Rope channels run under the coachroof back to the cockpit, removing deck -tripping hazards with lines running to positioned organisers on each side of the cockpit.

As we mentioned in Kraken News Issue 1, this mould is for the Kraken 50 version 2.0 and there are elements of the deck mould, which have been tweaked. The wrap-around saloon windows, for instance, have been improved aesthetically, the helm chair now provides better vision and support when heeling, and the cockpit is slightly larger overall.

Precision and detail are key to perfect plugs and our shipwrights know that attention to detail is rewarded when the mould is complete. Each section of both plugs are meticulously checked by our design team before giving the go ahead to proceed to the next step. Once both plugs have gone through lamination and painting, they are ready to make the female yacht moulds.